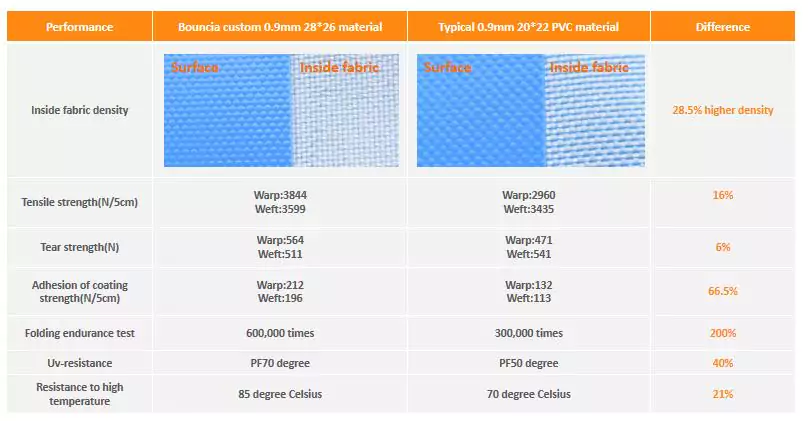

Floating water park equipment undergoes frequent use and exposure to various environmental conditions. The choice of materials not only determines the durability of the equipment but also directly impacts customer safety and operational costs. For water park investors, understanding the performance of different floating water park equipment material options is crucial to choosing the best materials for specific environments.

If you want to learn more about us or our products, welcome to leave a message below.

Copyright 2026 – Website by Guangzhou Bouncia Inflatables Limited. All Rights Reserved.